The automotive industry is one of the most important leading sectors in Germany and directly and indirectly employs a large number of skilled workers. SPÄH supports manufacturers and suppliers with customized solutions for the entire production process – from fittings, pumps and robotics to packaging and transport.

We also contribute our in-depth expertise to the development of new drive technologies, including e-mobility. Our components ensure reliable functionality, durability and maximum precision, enabling our partners to implement efficient, future-oriented mobility solutions.

The seal in the SPÄH vibration damper protects the electronic unit from cold, water, salt and dirt and also has damping properties.

Material: EPDM

Process: Punching

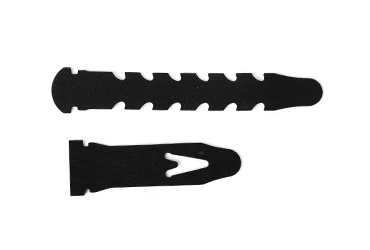

It’s nice if you never need it. But if you do, you need to find it quickly – the first aid kit. Our retaining strap always keeps the box firmly in the right place.

Material: Rubber Black

Process: Punching

The foam vibration dampers prevent possible vibrations and suppress any unpleasant background noise. This versatile product is used in many vehicles.

Material: Foam left on tape

Process: Punching (kiss-cut)

Our PU Collar material protects the leather in the armrest in the rear of a premium brand particularly well and also ensures a pleasant feel.

Material: PU Collar gray one-sided self-adhesive

Process: Punching

The small sheets are attached to the corresponding areas before the painting line to protect them from the paint being applied.

Material: UNITEC 300 green

Process: Punching (kiss-cut)

This small, inconspicuous plate replaces the coating on the control valves in many vehicles, thereby reducing friction and wear. The focus here is on maintaining tight tolerances.

Material: PTFE glass fabric film

Process engineering: Punching

This foam strip protects car doors in garages. The impact against the wall is absorbed and the doors remain intact.

Material: Foam

Process: Punching and gluing

The seal in the rear view camera protects the electronic unit from cold, water, salt and dirt and also has damping properties.

Material: EPDM

Process: Stamping

Our handle stands for a consistently high-quality feel. This gives the user a secure feeling when handling the loading unit.

Material: Rubber-Para

Process: Injection molding

As an experienced manufacturer of rubber and plastic parts, we develop and supply customized solutions for a wide range of applications in vehicle construction. Whether gaskets, molded parts or precisely manufactured components – thanks to state-of-the-art manufacturing processes and a wide range of materials, we ensure our customers maximum functionality, durability and flexibility. This makes us a reliable partner for the automotive industry and supports the mobility of tomorrow.

Do you have any questions, are you interested in our products or would you like a solution proposal for a specific requirement?

Please contact our support team.

Availability times: Mon.-Thurs. 8:00 – 16:00 | Fri. 8:00 – 12:00