We use additive manufacturing to create customized components for a wide range of applications – from functional prototypes and small series to series production.

Our technologies enable the production of complex geometries that would be difficult or impossible to realize using conventional processes. We process a wide range of non-metallic materials such as elastomers, plastics, soft fiber materials and many other sealing and insulation materials.

Each item is manufactured to customer specifications – tailored to the dimensions, material and required quantity – and provides precise, functional and flexible solutions for your individual requirements.

Do you need 3D components in individual or series production? Do you have a design project and are still looking for the right partner for development and production?

In our in-house 3D technology center, we offer you expert advice, precise production and tailor-made solutions – from functional prototypes to complex series components.

With state-of-the-art additive manufacturing and an experienced team, we ensure that your ideas are implemented efficiently, flexibly and to the highest quality. Welcome to SPÄH – your reliable partner for 3D solutions.

Multi Jet Fusion (MJF) is one of the fastest and most economical 3D printing processes for plastic parts – ideal for high-quality prototypes, functional parts and series production.

In combination with selected materials, MJF is particularly suitable for individual high-end components with precise details, high strength and consistent quality.

With our HP Multi Jet Fusion 5210, one of the most modern devices on the market, SPÄH offers decisive advantages, especially in the area of series production: efficient production processes, short delivery times and customized solutions that are precisely tailored to your requirements.

For additive manufacturing, we offer two high-quality materials that optimally combine diversity and functionality:

Polypropylene (PP)

PP is characterized by its extremely high resistance, is food-safe and particularly suitable for chemically resistant components. PP also enables the printing of film hinges, which means that innovative and flexible designs can be realized.

Polyamide 12 (PA12)

PA12 impresses with its balanced property profile, high stability and impact resistance. This makes it ideal for functional components, prototypes and applications where mechanical strength is required.

These materials enable us to produce a wide range of individual components with the highest precision and optimum material properties – perfectly tailored to your requirements and areas of application.

To make your 3D-printed components even more individual and efficient, we offer a wide range of post-processing options – tailored precisely to your requirements.

In addition to machining on our modern turning and milling centers, combination parts, such as inserted sealing lips, can also be produced without any problems.

Our post-processing options include, among others:

Trovalizing for edge rounding and surface improvement,

chemical smoothing for particularly even, dense and visually high-quality surfaces,

Coloring the products in different shades to customize your components,

as well as lacquering and smoothing to combine functionality and aesthetics in the best possible way.

With this range of methods, we ensure that your components not only meet the highest standards in terms of functionality, but also in terms of appearance, feel and durability.

Example: Suction cups for automation

Reworking: Inserting the sealing lip

Example: Lower part of an ultrasonic transducer

Reworking: Attachment of thread insert (thread cutting also possible)

Example: Bevel spur gear

Reworking: Grinding according to customer requirements

Material: PA 12

Process engineering: 3D printing

The design of the 3D-printed test gauge can be optimally adapted to the respective component. This enables material savings, streamlined testing processes and a reduction in rejects.

In addition, reduced stock levels and demand-oriented production cut costs. The test gauge arises directly from the application and supports sustainable, efficient and process-optimized production.

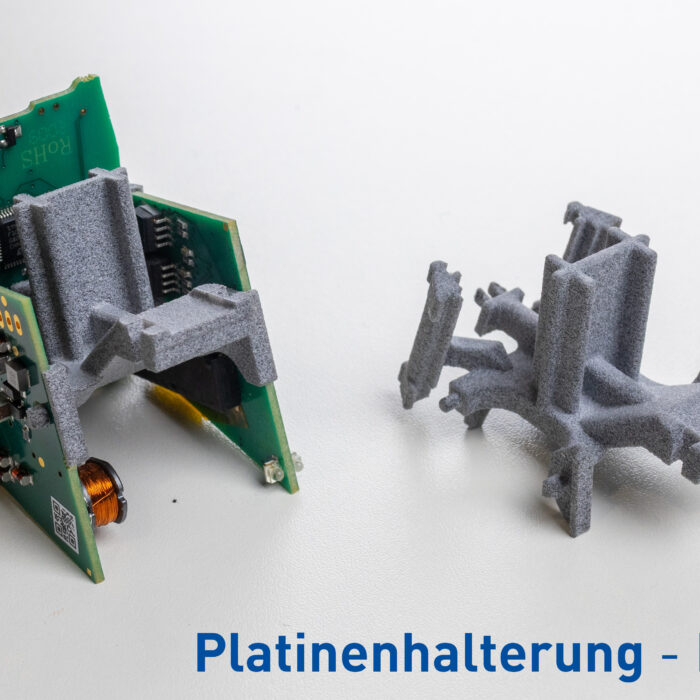

Material: PA 12

Process engineering: 3D printing

The 3D-printed circuit board holder enables a flexible arrangement of circuit boards around the component. This innovative design reduces heat generation and improves the cooling of electronic components. At the same time, the optimized PCB placement ensures significant space savings in the housing without restricting functionality.

Material: PA 12

Process engineering: 3D printing

The 3D-printed binomial structure offers a lightweight and highly stable construction for a wide range of applications. Complex geometries that are difficult to produce using conventional methods can be realized in this way.

The structure enables material savings, optimized load distribution and space-saving components. Flexible adaptation to requirements allows products to be developed more quickly, inventories to be reduced and production to be optimized in the long term.

Material: PP

Process engineering: 3D printing

The 3D-printed bunnies are a stylish and original customer gift that charmingly combines creativity and innovation. Available in various sizes and with a high-quality surface, they demonstrate the versatility of additive manufacturing.

Whether as an advertising medium, gift or decoration – the 3D bunnies make an impression and impressively demonstrate the possibilities of modern production.

Material: PA 12

Process engineering: 3D printing

This 3D-printed advertising material shows a detailed park bench scene under a tree with passers-by – including a 3D-printed figure of a SPÄH employee, made directly from a 3D scan.

The combination of realistic figures, detailed surroundings and individual customization shows how creative concepts can be implemented with additive manufacturing. The model is a striking advertising medium or special customer gift that impressively showcases creativity, innovation and the versatility of 3D printing.

Do you have any questions, are you interested in our seals or would you like a solution proposal for a specific requirement?

Please contact our support team.

Availability times: Mon.-Thurs. 8:00 – 16:00 | Fri. 8:00 – 12:00